Adhesive Tape Rewinder Set

BOPP/OPP ADHESIVE TAPE CUTTING MACHINE 2108C

Machine designed for cutting and rewinding BOPP/OPP packaging tapes.

– PAPER CORE LOADING MACHINE XW-105

Machine designed for automatic loading and unloading of paper core. Rewinding shaft mounted with air compressor at 5-7.5 kW

Main specifications:

Total weight: 312KG

Max. Packing: 2550*1200*1100mm

Min. Packing: 1520*900*1620mm

– XW-203 PAPER TUBE CUTTING

Machine used for cutting paper tubes.

Main specifications:

Max. Cutting Width: 500mm

Max. Thickness of Paper Tube: 5mm

Total Power: 1.5kw

Power Supply: 3 phases 380 V 50Hz

Weight: 500kg

Machine Dimensions: 1700*750*1100mm.

MINI REWINDER XW-805A

Equipment used to rewind adhesive tapes.

Main specifications:

Tube core inner diameter: 3 inches

Maximum bearing diameter: 300 mm

Rewinding speed: 150 m/min

Total Power: 1/2 HP

Total Weight: 120 kg

Machine Dimensions: 550*450*550 m

APPLICATION

The box strapping machine is a device that replaces outdated methods of strapping boxes with staples and can be widely used in various industries, such as: electronics, food, textiles, postal services, printing, among others. It straps boxes, wicker boxes, paper packages, fabric packages, among various other applications.

Automatic strapping machine with virgin or recycled polypropylene tape. It uses straps from 10 to 16 mm. Compact and lightweight design. With this machine, it is possible to strap (apply tape) to small and medium-sized boxes automatically.

ADVANTAGES

- High standard of engineering and simple design;

- Easy operation and simple maintenance;

- Stainless steel cover;

- Mechanical tension control of the tape;

- Economy, the motor only operates when activated.

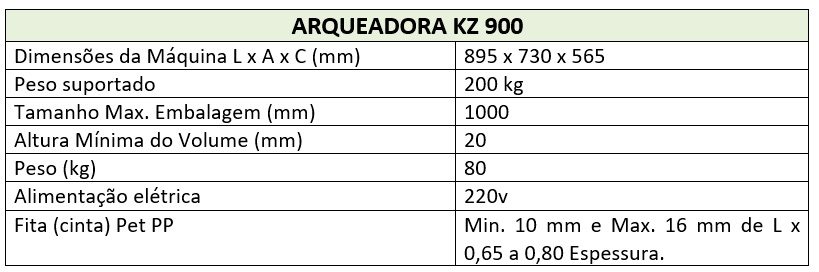

KZ 900 Strapping Machine

SEMI-AUTOMATIC MACHINE FOR CLOSING WITH STRAPPING TAPE MODEL KZ 900.

SCOPE OF APPLICATION:

The box strapping machine is a device designed to strap boxes by wrapping them with polypropylene straps, aiming to reinforce, protect, and compact loads, improving their storage. It is a modern machine that replaces the traditional method of strapping boxes, being more agile, cost-effective, and also prevents operator fatigue. The automatic strapping machine accepts various sizes of boxes, making it ideal for all types of packaging and highly recommended for PP straps ranging from 10 to 16 mm without the need for machine adjustments.

Its control panel is strategically located, and its operation is performed simply and automatically, with the operator only needing to place the box on the machine in the desired position for the straps. It is a equipment that offers total safety in its operation, with an intelligent system where the machine automatically pauses its operation after 60 seconds of inactivity.

APPLICATION

The box strapping machine is a device that replaces outdated methods of strapping boxes with staples and can be widely used in various industries, such as: electronics, food, textiles, postal services, printing, among others. It straps boxes, wicker boxes, paper packages, fabric packages, among various other applications.

Automatic strapping machine with virgin or recycled polypropylene tape. It uses straps from 10 to 16 mm. Compact and lightweight design. With this machine, it is possible to strap (apply tape) to small and medium-sized boxes automatically.

ADVANTAGES

- High standard of engineering and simple design;

- Easy operation and simple maintenance;

- Stainless steel cover;

- Mechanical tension control of the tape;

- Economy, the motor only operates when activated.