L-Pneumatic Sealer with BSA 450 Tunnel

PNEUMATIC L-SEALER DFQC450

Pneumatic L-sealer, with a structure entirely in carbon steel. Incorporates the latest requirements regarding hygiene and ease of cleaning. The sealing is activated by a pneumatic cylinder, with an L-shaped sealing bar with nickel-chromium sealing blades. Height adjustment of the exit conveyor via a handwheel. The sealer features three timers: conveyor time, sealing time, and automatic time.

ADVANTAGES:

- Electric Shock and Burn Protection Sensor;

- Sealing Bar Protection;

- Solid structure with quality spare parts;

- Approximate production of 8 to 12 packages per minute;

- Sealing size is adjustable according to the package.

BSA 450 TUNNEL

The BSA 450 Tunnel is developed with internally circulated hot air. The tunnel consists of rollers covered with silicone tubes. The temperature inside the tunnel is controlled by an electronic temperature controller. The shrink tunnel can be widely used where shrink-wrapping of packaging films is required, such as egg packaging, graphic products, food, beverages, pharmaceuticals, CDs, hardware, cosmetics, books, toys, electronics, etc.

ADVANTAGES:

- Low maintenance costs;

- Digital panel;

- Conveyor speed adjustments;

- Temperature control;

- High efficiency and agility;

- Activation of the internal ventilation system.

Dados

Técnicos

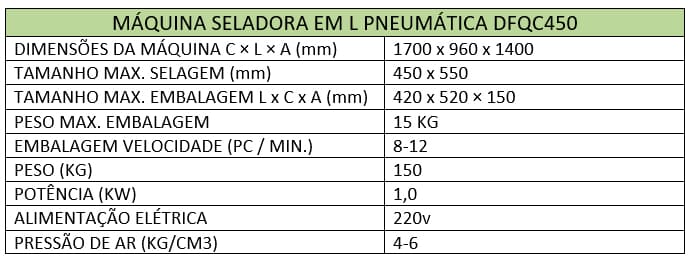

Technical Specifications - Sealer

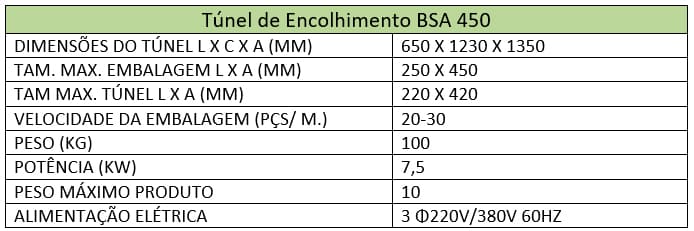

Technical Specifications - Tunnel