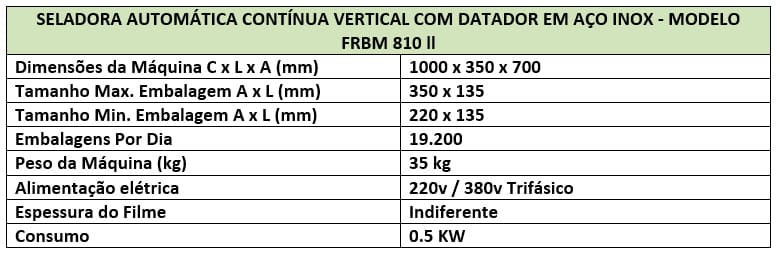

Vertical Automatic Continuous Sealer With Stainless Steel Date Coder

FRBM 810 II

APPLICATION SCOPE

The Automatic Continuous Sealer is ideal for continuous production lines that need to seal bags of various products efficiently and quickly. It features a control panel where the operator can easily and intuitively adjust the sealing temperature and conveyor belt speed. Its use is straightforward and can be handled by just one operator. Made from stainless steel, it includes an efficient internal cooling system, and offers sealing temperature adjustment from 0 to 300°C, making it suitable for various packaging thicknesses.

This sealer model was developed to expedite production and reduce manual labor in processes. As a machine with a conveyor belt, the process becomes continuous, allowing the operator to work more efficiently and reducing fatigue. This equipment can seal approximately 19,200 packages per day.

The Automatic Continuous Sealer provides the highest quality sealing, handling a wide variety of packaging efficiently and durably. It seals packages made of aluminum, BOPP, Polyethylene, Polypropylene, Polynylon, Medical-grade Paper, Solapa (with lamination, used in spices, condiments, honey, etc.), and more. The automatic sealer can seal any plastic packaging.

The date coder operates through thermal transfer, where the digits and letters are heated and, along with the ink, stamped onto the packaging with the necessary information, such as manufacturing date, expiration date, and batch number. The date is extremely tamper-proof and can be stored in harsh and cold environments such as freezers, cold storage rooms, display units, etc. The dating system is highly economical, capable of dating up to approximately 100,000 packages.

APPLICATION

With the automatic sealer, you can seal any type of packaging because the machine has temperature and speed control. Due to the TEFLON thermal insulation, the heating element does not come into direct contact with the packaging, allowing you to seal any type of plastic, such as medical-grade paper and blister packs (e.g. packaging for spices, condiments, honey, among other products). It can also seal PE, PP, BOPP, PET, medical grade, and other materials. This model allows you to seal PAPER + PLASTIC combinations, which are packaging types with blister packs and solapas, thereby reducing manual labor for stapling and improving the finish. To seal blister packs, simply increase the temperature to approximately 280 degrees and reduce the speed, ensuring both the packaging and the blister pack in the plastic are sealed.

CONVEYOR BELT WITH SIMPLE ADJUSTMENT

The sealer's conveyor belt has a load capacity of 5 kg, adjustable height, and speed, making product supply suitable for a wide range of applications, capable of sealing small to large products.

ADJUSTMENTS ON JAWS

The machine also features adjustments on its jaws, allowing whether for more, or less pressure during sealing, which is ideal for thicker packaging that requires greater pressure for perfect sealing.

Seladora Automática Contínua Vertical com Datador em Aço Carbono

FRBM 810 II

This sealer model was developed to streamline productions and reduce manual labor in processes. Since it is a machine with a conveyor belt, the process becomes continuous, allowing the operator to work more quickly and reducing fatigue. This equipment can seal up to approximately 19,200 packages per day. Its adjustments are straightforward, enabling the operator to handle the equipment with ease and without significant issues. It is possible to adjust the sealing temperature, which varies according to the thickness and type of the bag, as well as the speed of the conveyor belt.

With a sealing width ranging from 6 to 15 mm and a temperature range from 0°C to 300°C, the sealing becomes extremely reliable, capable of sealing even products containing liquids, such as sauces and preserves.

DATE CODER

The date coder works through thermal transfer, where the digits and letters are heated and, along with the ink, are stamped onto the packaging with the necessary information such as manufacturing date, expiration date, and batch number. The date is extremely tamper-proof, allowing it to be stored in harsh and cold environments such as freezers, cold storage rooms, display units, and more.

- Simple adjustments

- Sealing temperature adjustment

- Conveyor belt height adjustment

- Variety of applications

- Seals even products with sauces and preserves

- Date coder

- Date coder prints up to 45 characters

- Prints date on up to 100,000 packages without needing to refill the ink

- Can handle products up to 5 kg

- Teflon thermal insulation

- Produces up to 19,000 bags in an 8-hour workday

- Robust and durable

- Made from carbon steel

- Sealing width of 6 to 15 mm

- Temperature range from 0 to 300°C

- Low maintenance costs;

- Excellent cost-effectiveness.