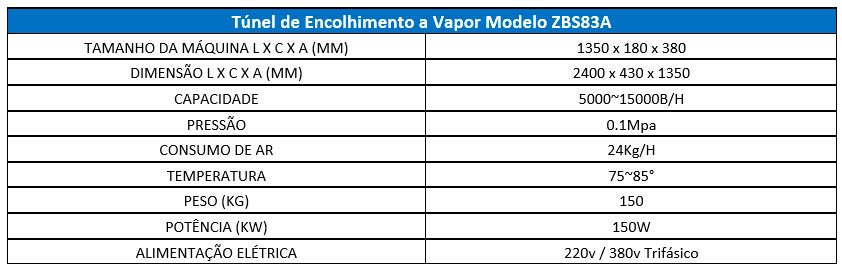

Steam Shrink Tunnel with Steam Generator ZBS 83 A

APPLICATION

The steam shrink tunnel is a perfect equipment to meet the demands of products where packaging or labels require shrink wrapping, using a highly efficient steam heating system. It is a robust equipment with an easy-to-operate panel, temperature adjustment, conveyor speed adjustments, adjustable power, and integrated steam generator.

By conducting shrink wrapping through steam heating, the label becomes more uniform, and the risk of packaging deformation is virtually zero.

ABOUT THE PRODUCT

This equipment is extremely productive and can be continuously supplied and integrated into a production line, as its conveyor can reach speeds of up to 10 m/min, increasing productivity.

Its application is wide-ranging and can be used in the food, chemical, pharmaceutical industries, as well as any other sector requiring shrink wrapping. It is mainly used for beverage bottles, cosmetic bottles such as shampoo, conditioner, hair spray, general spray bottles, among various other products.

OPERATION

Its operation is simple, without requiring the operator to make complex adjustments. The panel features an emergency button and conveyor speed adjustment

KEY FEATURES

Integrated steam generator

Steam heating

Enhanced uniformity of packaging

High productivity

Robust equipment

Fully constructed in stainless steel

Low energy consumption

Reduction in labor requirements

High durability

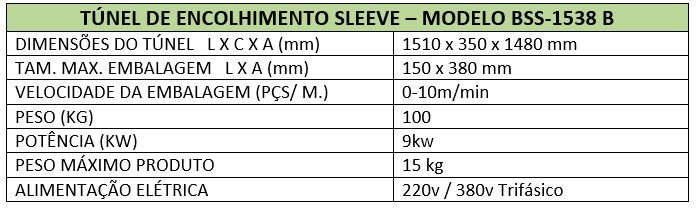

Shrink Sleeve Stainless Steel Tunnel for Seals and Labels BSS 1538 B

Shrink Sleeve Tunnel - MODEL BSS 1538 B

The BSS-1538 B shrink sleeve tunnel features a resistance system, entirely controlled by the equipment operator through visible adjustments on a digital panel, making resistance control intuitive and easy to handle. The heating elements are located at the bottom of the conveyor and on the sides of the machine, ensuring uniform and evenly distributed heating of the material wrapping the products to be packaged. The conveyor speed of the shrink tunnel is easily adjustable according to the customer's product, accessible on its control panel, making the product enveloping process more efficient. This makes the BSS-1538 B shrink tunnel the best solution for your company, whether it is small, medium, or large.

APPLICATION

The BSS-1538 B shrink tunnel can be used for shrink-wrapping plastic films around products such as water bottles, sauce bottles, beverage bottles, among others. The equipment is primarily designed for manufacturing plants, stores, and industries of all sizes, making it the ideal and safe solution for your company.

KEY FEATURES

Ideal Sleeve format for bottles;

Stainless steel construction;

Digital control panel;

Independent control of heating elements;

Simple adjustment of heating elements;

8 heating elements;

Easy adjustment accessible from the control panel;

Conveyor supports up to 15 kg;

Easy operation;

Low maintenance;

Conveyor speed with multiple adjustable levels.

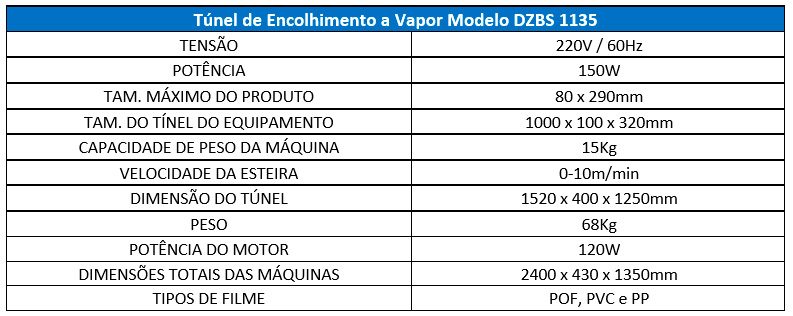

Shrink Steam Tunnel DZBS 1135 with Steam Generator

APPLICATION

The steam shrink tunnel is a perfect equipment to meet the demands of products where packaging or labels require shrink wrapping, using a highly efficient steam heating system. It is a robust equipment with an easy-to-operate panel, temperature adjustment, conveyor speed adjustments, adjustable power, and integrated steam generator.

By conducting shrink wrapping through steam heating, the label becomes more uniform, and the risk of packaging deformation is virtually zero.

ABOUT THE PRODUCT

This equipment is extremely productive and can be continuously supplied and integrated into a production line, as its conveyor can reach speeds of up to 10 m/min, increasing productivity.

Its application is wide-ranging and can be used in the food, chemical, pharmaceutical industries, as well as any other sector requiring shrink wrapping. It is mainly used for beverage bottles, cosmetic bottles such as shampoo, conditioner, hair spray, general spray bottles, among various other products.

OPERATION

Its operation is simple, without requiring the operator to make complex adjustments. The panel features an emergency button and conveyor speed adjustment

KEY FEATURES

Integrated steam generator

Steam heating

Enhanced uniformity of packaging

High productivity

Robust equipment

Fully constructed in stainless steel

Low energy consumption

Reduction in labor requirements

High durability