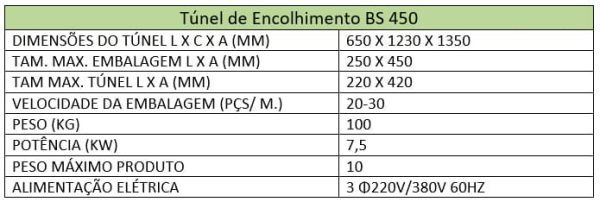

APPLICATION

The BS 450 Tunnel is designed with internal circulation of hot air. The tunnel is comprised of rollers covered with silicone tubes. The temperature inside the tunnel is controlled by an electronic temperature controller. The shrink tunnel can be widely used where packaging films need to be shrunk, such as egg packaging, graphic products, food, beverages, pharmaceuticals, CDs, hardware, cosmetics, books, toys, electronic products, and more.

This model uses a system of resistors and infrared quartz tubes that are responsible for distributing heat evenly and precisely, in the exact amount to leave the packaging uniform without causing any damage to the product.

The BSA 450 tunnel uses thermo-shrinkable plastics mainly made of PVC, PP, POF,

covering a good variety of materials that can be used in shrink wrapping.

ADVANTAGES

-

- Digital panel

- Temperature control

- Conveyor speed adjustments

- Temperature range up to 300°C

- Conveyor speed of up to 10 meters per minute

- High efficiency and speed

- Resistance temperature adjustment

- Activation of internal ventilation system

- Heating by resistors

- Infrared quartz

- Low maintenance costs

- Energy saving